An estimated 60% of all eye injuries occur at work, which adds up to around 30,000 work-related eye injuries every year in Australia. The vast majority of these eye injuries could be prevented by following proper safety procedures and wearing appropriate personal protective equipment (PPE).

What are the 3 Types of Eye Protection?

The three main types of eye protection are safety glasses, goggles and face shields. Each type has a different structure to perform various tasks to ensure the protection of workers from eye or face injuries.

Safety Glasses

Safety glasses or spectacles are impact rated glasses that protect the eyes. They are ideal for protection from head-on and, in some cases, side-on impact. The maximum protection safety glasses can offer is medium impact.

Safety Glasses come in various shapes, sizes and models. To ensure you select the right style for you, consider the different features below.

- Side Arms: adjustable angle, soft arms (full or lined), solid arms and soft temple tips

- Frame: full-frame, semi-frame and frameless

- Nose Bridge: soft and solid

- Size: small and regular

- Function: dust guards, over spectacles, bi-focal and prescription

- Lens: material, VLT and coatings

|

|

|

|

|

Safety Goggles

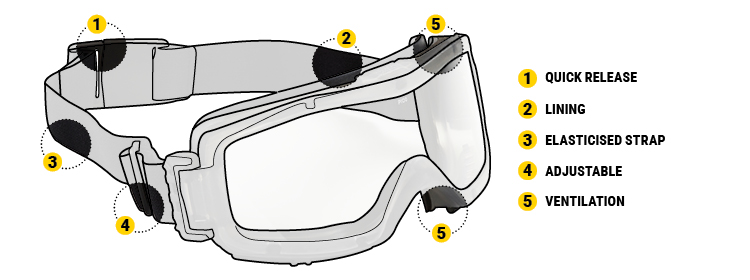

Safety goggles provide a complete seal around the eyes, which makes them the most suitable choice for working environments where hazards such as chemical splash or a high level of airborne particles are present. Goggles are available in many different styles each being specific to different work environments. When selecting safety goggles, you should take into account tint and impact rating as well as lens type, lining, venting and additional guards.

Safety Goggle Lining

|

Open cell foam is typically the most comfortable liner, and it absorbs moisture which provides added comfort in hot and humid conditions. This also makes the liner more likely to collect dirt, grime and other contaminates. Closed cell foam is a strong and durable liner that does not collect dirt and grime and is less likely to absorb moisture, which makes it a more hygienic option than open cell foam. No foam liner provides an uninterrupted seal with adapts better to the face than foam. There is a reduced risk of any moisture absorption, which makes this the most hygienic option. |

|

Safety Goggle Venting

The venting option you choose will relate directly to your working environment. Vents are ideal for airflow and they reduce the chance of fogging but create gaps where hazards can enter the protected eye area.

|

Direct vent goggles have multiple vents around the goggle which assist with airflow and reduce lens fogging. Direct vent goggles are mainly used for impact protection and are not suitable for liquid, dust or vapor protection. |

|

Indirect vent goggles have slightly covered vents that provide better protection from liquid splash, dust and other airborne particles in comparison to direct vents, while still allowing airflow to reduce lens fog. |

|

Top vent closed goggles have direct and indirect vents on the lower half of the frame, but closed vents on the upper half of the frame. This style provides protection against any potential splash to the top of the goggle. |

|

Closed vent goggles are completely sealed with no vents. They provide excellent protection from impact, splash, dust and vapors. Due to lack of airflow, goggles fog up quickly, so an anti-fog lens is necessary. When dealing with hazardous vapor, always use closed vent goggles. |

Face Shields

Face shields protect the face from the front and side-on impact. In most cases, face shields should be worn in conjunction with safety glasses or goggles for an added layer of protection. Face shields achieve high or extra high impact protection.

|

|

|

|

|

When should Eye Protection be worn?

Impact-rated eye protection must be worn whenever there is a risk of an outside contaminant, visible or not, making contact with the eye that could potentially cause damage. Impact-rated eye protection must be worn:

- During sawing, chipping, grinding, machining or drilling.

- When there is potential exposure to chemicals or chemical splash.

- When degreasing, plating or handling acids or chemicals.

- When exposed to UV radiation or intense light.

- During welding, casting or hot dipping.

- In high heat scenarios.

- When there is a risk of projectiles or dust particles entering the eye.

6 Key Hazards and Risks to consider before selecting your Eye Protection

AS/NZS 1336:2014 stipulates that eye-related hazards and risks must be assessed and evaluated before selecting eye protection for a particular task or area. When selecting the appropriate eye protection, consider the following:

|

|

The four major hazards associated with eye protection

| Projectiles and Dust Particles | Chemical | Heat | UV Exposure |

Eye Protection Impact Rating & Markings

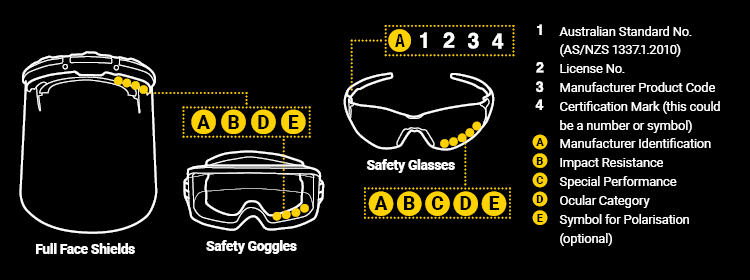

Safety eyewear should be compliant with AS/NZS 1337.1 - Eye and face protectors for occupational applications and/or with AS/NZS 1337.6 - Prescription eye protectors against low and medium impact. If a product is certified to one of these standards they will display the certifier's logo on the packaging.

|

In addition to these logos, eyewear will have a number of markings to indicate the applications and environments it is suitable for, including impact rating and protection against specific hazards. |

|||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

|

The maximum impact rating safety glasses can achieve is medium impact; high ratings can only be achieved when the face is protected by a full face shield. When selecting safety glasses, goggles or face shields keep an eye out for the markings on the lens and the side arms for information on the rating and standards that apply to that particular product. |

How to Select Eye Protection

Selecting the correct eye protection for the job at hand is crucial to the safety of a worker. There are various factors that need to be considered when selecting The different eye protection options (safety glasses, goggles and face shields) are available in many different styles, each being specific to different work environments.

Select Lens Material

There are two primary lens materials used in eye protection, they are polycarbonate and acetate.

Polycarbonate is rated to medium and high impact under AS/NZS 1337.1.2010. It is much stronger than most other plastics and delivers excellent heat resistance. Polycarbonate is also lightweight and provides good optical clarity.

Acetate is rated to medium impact under AS/NZS 1337.1.2010. It is very light and flexible and provides good optical clarity due to its scratch resistance. Often, acetate lenses are charged at a more premium cost.

Select Lens Tint

There are 10 different lens tint colours to choose from, each suited for different applications.

| Lens | Application | Available in | Description | VLT Category | VLT% |

Clear |

Indoor | Glasses; Goggles; Face Shield | Provides impact protection or general-purpose applications where there is little to no glare, such as indoor or underground workplaces. the clear lens provides true colour recognition. | 0 | 80% - 100% |

Amber |

Indoor & Outdoor | Glasses | Suitable for indoor and outdoor low light environments. The amber tint enhances light and improves contrast. | 0 | 80%- 100% |

Mirror |

Indoor & Outdoor | Glasses | A slightly tinted lens that is suitable when working indoors and outdoors to reduce sun glare. | 1 | 43%-80% |

|

Brown |

Outdoor | Glasses | Suitable for work environments with varying light conditions. The brown lens improves contrast and reduces glare. | 2 | 18%-43% |

Blue |

Indoor | Glasses | Helps reduce glare from artificial light sources such as halogen and fluorescent lights. | 0 | 80%-100% |

Grey/Smoke |

Outdoor | Glasses; Goggles; Face Shield | Suitable for outdoor environments where there is direct exposure to sunlight. Reduces glare and eye strain while assisting with colour recognition. | 3 | 9%-18% |

Polarised |

Outdoor | Glasses | Suitable for environments with high glare, such as marine or offshore sites. Protects against the sun's UV rays. | 3 | 9%-18% |

Transitional |

Indoor & Outdoor | Glasses | Suitable for work environments where the lighting varies or the wearer is shifting between indoor and outdoor areas. The lens will automatically transition to suit the environment. | 0-3 | 9%-100% |

Shade 3/5 |

Indoor & Outdoor | Face Shield | Provides protection from radiation caused by gas welding or oxygen cutting. | N/A | N/A |

Arc |

Indoor & Outdoor | Face Shield | Protects against arc flash. Available in various shades depending on the requirements of the work environment. | ||