Working at Heights Regulations

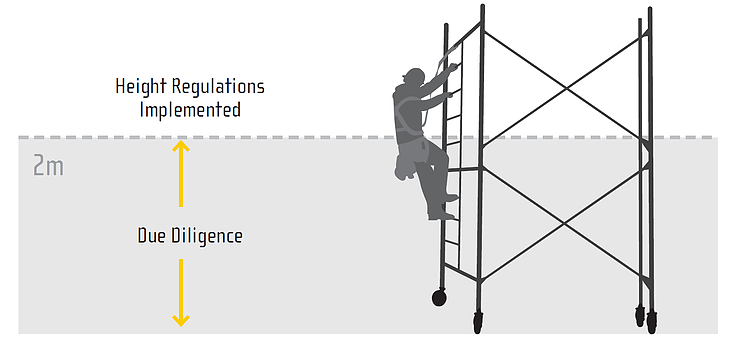

Workplace Health and Safety (WHS) height safety regulations come into effect once workers are required to complete a task over 2m above ground. Under this height, worksites should use due diligence to assess potential fall hazards and ensure they are appropriately managed. Work conducted over a height of 2m is considered ‘high fall risk’, which requires worksites to manage this risk by implementing reasonable and practical controls.

|

In order to manage risk under WHS regulations the persons with the primary duty of care are required to:

|

|

Once this review has been completed, the WHS Act requires those with a duty of care to consult their workers and allow them to comment on any actions that will directly impact their own health and safety. These comments must be taken into account during the risk management process.

Hierarchy of Controls for Preventing or Reducing the Risk of Falls

Ensuring the correct risk management control is implemented can be complex and entirely dependent on the job at hand. For example, the fall risk could potentially be eliminated as the job could be performed at ground level or mitigating the risk may be your only option. Deciding which control is most appropriate for your job is simple with the ATOM Safety's hierarchy of controls.

Eliminate RiskEliminate fall risk entirely by completing the job at ground level. Utilise extension poles or other devices to reach items, install equipment at ground level or lower broken equipment to the ground for repair. |

Reduce RiskIf eliminating risk isn't possible, determine ways to reduce it. Complete tasks at ground level to minimise time spent at height or complete tasks at a lower height to reduce potential fall distance. |

Fall PreventionIf you can't eliminate or reduce risk, fall prevention devices create a barrier between the worker and risk area to prevent falling (e.g. guard railing and elevated work platforms (EWP)). |

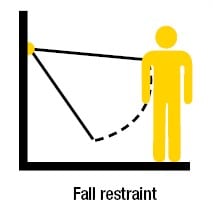

Fall Restraint SystemsIf fall prevention barriers aren't practical, restrict worker's movements with fall restraint systems. These systems anchor the worker to a central point, limiting movement to only where work is being conducted. |

Fall Arrest SystemsIf previous scenarios aren't possible, use a fall arrest system. Fall arrest systems help reduce the severity of potential injuries caused by a fall (e.g. fall protection systems, safety nets, and catch platforms). |

Note: While safety nets are designed to arrest falls, they should not be used as a sole fall protection method. Always use safety nets in conjunction with edge protection and fall protection systems.

Fall Restraint and Fall ArrestAlthough they sound similar, fall restraint and fall arrest are two different things. Fall restraint is a strategy that prevents a worker from falling. Utilising a Type 1 device, workers are prevented from moving into a hazardous position from which they may fall. Fall arrest is a strategy that aims to reduce the impact of a fall. In a fall arrest system, a worker will be allowed to fall and the system minimises injury as much as possible by ensuring they do not fall onto a platform or object below, and by using technologies such as shock absorption. This strategy utilises Type 1,2,3 and 4 devices. |

|

| Type 1 fall arrestors are manually adjusted devices that are attached to a fixed anchorage line. They can move up and down the fixed-line and keep the user in a fall restraint position. Type 2 fall arrestors are automatically retracting devices that lock when loaded with a fallen worker's weight, which provides fall arrest. They are usually attached to fixed anchorage points and include self-retracting lifelines, personal fall limiters and inertia reels. Type 3 fall arrestors are similar to Type 2 fall arrestors but with an inbuilt retrieval mechanism that helps in rescue situations. Type 4 fall arrestors are similar to Type 2 fall arrestors but with an inbuilt self-rescue feature. |  |

How to Work Safely on a Roof

Due to the WHS height safety regulations, most work conducted on a roof is considered ‘high risk’. Working on a roof is also deemed high risk when demolition has occurred that may impact load-bearing structures of the roof or will impact the structural integrity; work involving the disturbance of asbestos; and work is to be carried out on or near live electrical installations or services. Working on a roof offers additional hazards caused by the nature of the job, including weather conditions, fragile or sloping surfaces and steep pitches. Below are guidelines you should also stick to when working on roofs.

Fragile & Slopping Surfaces

Roofing materials vary in fragility and should always be treated with caution when being worked on. Fragile roofing material includes asbestos roof sheets; polycarbonate (commonly used in skylights); fibre cement sheets; corroded metal sheets or fasteners; glass; chipboard or rotted wood material; and slates of tiles. These materials increase a worker's risk of falling through the roof as opposed to off it and when they are identified, control measures should always be put in place. Control measures include using EWPs; walkways or crawl boards; fall prevention barriers; signs to signify dangerous areas; and fall arrest systems.

If a roof slope is over 35 degrees, it should not be stood or worked on, as it increases the likelihood of a worker slipping. Fall prevention controls, such as guard rails or catch platforms, are not suitable measures to help protect workers. If you need to access an area with a slope over 35 degrees, use aerial equipment (e.g. cherry picker), travel restraint, industrial rope access system or scaffolding platforms.

Weather Conditions

What you do when you've had a fall?

Everyone at a worksite should be trained in how to act in the event of a fall, including relevant first aid and how to safely conduct a rescue.

What is Total Fall Distance?

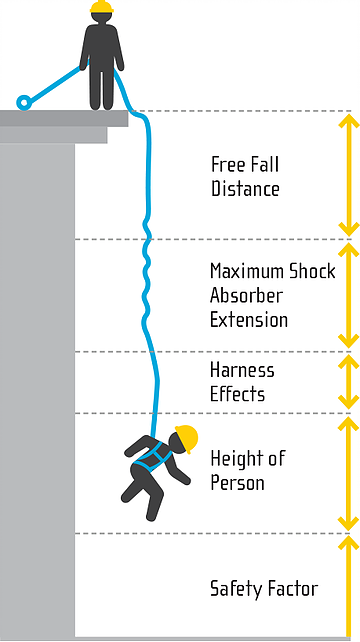

Knowing total fall distance is vital to any height safety risk management plan. Total fall distance provides insight into what fall protection system is appropriate for each job. Knowing the total fall distance is just as important as having the proper equipment. Total fall distance must be less than the distance between the working surface and the next closest object in the fall path.

Total Fall Distance = Free Fall Distance + Maximum Shock Absorber Extension + Harness Effects + Height of Person + Safety Factor

Free Fall DistanceFree fall distance is the amount of vertical free fall experienced between the initial start of the fall and the point where the shock-absorbing system kicks in. As per Australian regulations, free fall distance must not exceed 2m. Free Fall Distance = Length of Lanyard - (Distance Between Anchor Point and Working Surface + Distance Between Worker's Lanyard Attachment and Working Surface) Tip: To decrease free fall distance always keep the anchor point as far from the attachment point on the harness as possible. Maximum Shock Absorber ExtensionThe maximum shock absorber extension is the vertical distance travelled when the shock-absorbing mechanism is activated and final arrest occurs. Every lanyard or SRL will have its shock-absorbing distance labelled with a lanyard's maximum extension being 1.75m and an SRL's maximum extension being 0.7m. Harness EffectHarness effects take into account the stretch of the safety harness during fall arrest. In most circumstances, this can be estimated to be approximately 0.3m. Height of PersonHeight of person = Height of Worker - Distance Between the Top of the Worker's Head and the Lanyard Attachment. Safety FactorIncluding a safety factor, ensures adequate clearance between the worker and the platform below. It is recommended your safety factor be at least 1m. |

|

The Essential Components of a Fall Protection System

The ABCs of fall protection refer to the essential components of an effective fall protection system.

AnchorageAnchorage connectors provide a secure point of attachment to an existing structure. They can be temporary or permanent and must support 15kN(1500kg) for a single person or 21kN for a two-person anchorage. |

Body SupportBody support refers to the full-body safety harness worn by workers to support their weight and connect them to anchorage points. Safety harnesses must always be properly fitted. Learn more about body support. |

ConnectorsConnectors attach the harness to the anchorage. The most common connectors are shock-absorbing lanyards and self-retracting lifelines, which are designed to reduce the force of a fall. Learn more about connectors. |

Descent/RescueDescent and rescue systems are used for the retrieval of a worker who may be injured or otherwise incapacitated, often due to a fall or entrapment in a confined space. |

EducationEducation on fall protection and fall arrest is essential. Employees should ensure their workers are adequately trained before working at heights. |

Fall Protection for ToolsPreventing dropped object incidents is an important aspect of working safely at heights. Learn more about fall protection for tools. |

To think this is only an overview of a few of the different aspects regarding working at heights. For a deeper dive into height safety, check out our Safety Harness or Lanyard or a Lifeline page.

If you have any questions regarding working at heights, contact your local ATOM Safety representative today.