Why are Glove Standards Important?

Understanding EN Standards:

These test results should not be interpreted as meaning the glove is definitely suitable or not for a specific application. To determine if a glove is fit for purpose, practical trials are recommended. Testing and evaluation is critical to any risk assessment process when selecting safety gloves.

The three risk categories under EN standards:

Risk Category I: Gloves of Simple Design for Minimal Risk Only

Risk Category II: Gloves of Intermediate Design for Intermediate Risk

|

These gloves are designed to provide protection against intermediate risk. Gloves in this category must undergo independent testing and certification by a notified body. Only approved gloves may be issued with a CE mark (as shown below), enabling the gloves to be sold. If gloves do not receive this mark, they cannot be sold.

The instructions for use of the gloves will specify the name and address of the notified body that certified the product. Each notified body has its own identification mark.

An example of this category would be gloves requiring good cut, puncture and abrasion performance.

|

Risk Category III: Gloves of Complex Design for Irreversible or Mortal Risk

|

Gloves within this category are designed to protect the user against the highest levels of risk. These gloves must be tested and certified by a notified body. As well as this, the quality assurance system used by the manufacturer to guarantee consistency throughout production must be independently checked. The notified body performing the evaluation will be identified by their number which must appear next to the CE mark on the gloves (as shown below). Gloves providing protection against chemicals would be an example of this risk category. |

EN Glove Standards

EN420 (AS/NZS 2161.2:1998)

General Requirements for Protective Gloves

This standard outlines general requirements that enable a safety glove to be sold. These requirements include glove design and construction, comfort and efficiency, innocuousness (must not cause any harm to the user), as well as the marking and information relevant to all protective gloves.

EN374 (AS/NZS 2161.10:2005)

Gloves Giving Protection from Chemicals and Micro-Organisms

This standard outlines the capability of gloves to protect the user against chemicals and/or micro-organisms. The below pictogram is used to represent this standard and it must be accompanied by a minimum three digit code.

|

This code refers to the letter that is used to represent that chemical (from a list of 18 standard defined chemicals), for which a breakthrough time of at least 30 minutes must be achieved. If the pictogram is not accompanied by this code it means it can only withstand 1 chemical for only a short period of time. |

|

|

The micro-organism pictogram shown to the left is used when the glove conforms to at least a performance level 2 for the penetration test. The specific micro-organism that the glove provides protection against (if any) will be listed below the biohazard symbol shown below. |

EN388 (AS/NZS 2161.3:2020)

Gloves Giving Protection from Mechanical Risks

|

This standard is used for protective gloves in regards to physical and mechanical aggression caused by abrasion, blade cut, puncture, tearing, straight blade cut and impact protection. Protection against mechanical hazards is expressed on the glove by this pictogram. This pictogram should then be followed by five numbers relating to performance levels, with each number representing the test performed against a specific hazard. It will also include an indication of pass, fail or not tested for impact resistance |

EN407 (AS/NZS 2161.4:1999)

Gloves Giving Protection from Heat

This standard applies to gloves for thermal performance or protection against heat and/or fire. This is expressed using the below pictogram. Below the pictogram will be a series of 6 digits (relating to performance levels) which represent specific protective qualities.

|

The letters for protective quality are:

A = Flammability Resistance

B = Contact Heat Resistance

C = Convective Heat Resistance

D = Radiant Heat Resistance

E = Resistance to Small Splashes of Molten Metal

|

EN421 (AS/NZS 2161.1:2005)

EN421 is a European Standard that is also utilised in Australia to specify the test methods and requirements for gloves that claim to provide protection against ionising radiation and radioactive contamination. EN421 PPE glove standards apply to gloves that provide protection for arms and shoulders as well as hands, including those that are mounted in permanent containment enclosures, or intermediary sleeves used between gloves and permanent containment enclosures. It should be noted, the requirements of this standard don’t apply to protective gloves against x-ray radiation.

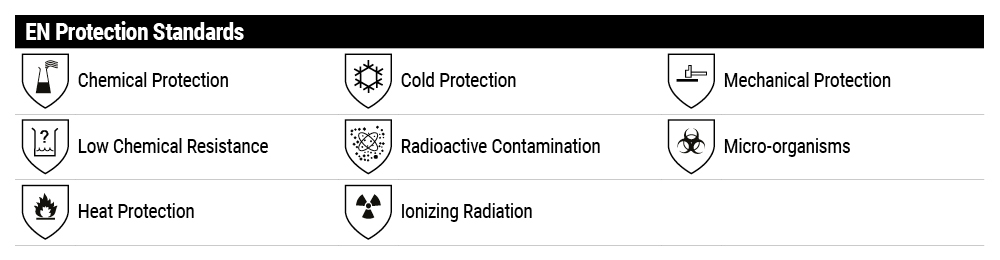

There are different pictograms relating to the glove’s specific protective qualities. These pictograms are used on the gloves to show the nature of the protection the glove provides.

|

Gloves that pass the tests for protection from radioactive contamination (also known as radiation gloves) use this pictogram. |

|

|

This pictogram is used on gloves that pass the tests for protection from ionising radiation. |

EN511 (AS/NZS 2161.5:1998)

Gloves Giving Protection from Cold

EN511 is a European glove standard that is utilised in Australia to measure how well a glove can withstand cold temperatures. It is just as important to protect your hands from cold burns in cold environments as it is to protect your hands from extreme heat. This goes beyond just finding work gloves that keep hands warm, but rather finding gloves that will protect hands from being harmed in cold environments. EN511 PPE glove standards only apply to gloves that provide protection to a user’s hands against convective and contact cold down to temperatures of - 50°C.

|

The testing criteria for protection from cold includes the following:

A = Resistance to convective cold (Performance level 0-4)

B = Resistance to contact cold (Performance level 0-4)

C = Permeability by water (Level 0 or 1)

|

For more detailed information on each glove standard, follow the links to their own blog posts or check out our range of blogs on hand protection.

You can also view our range of hand protection here

If you have further questions or need assistance with hand protection, contact the experts at ATOM Safety.