Why Wear A Respirator?

When inhaled, airborne particles, fumes and vapors can damage the delicate tissue inside the respiratory system. This damage can cause illness and increase the risk of respiratory diseases. These particles can have a harmful, possibly fatal impact on organs including kidneys, liver and central nervous system.

What are the best respirators for your workplace? Every worksite is different, a risk assessment needs be conducted to determine what respiratory hazards are present so appropriate respiratory protection can be selected.

How To Choose A Respirator

Selecting the correct respiratory protection is vital. There are many hazards in the workplace that can cause both short and long term respiratory damage. Below is a breakdown of the different types and styles of respirator masks available to help protect workers. If you are unsure of your requirements, or would like further assistance please contact ATOM Safety who can make custom recommendations on the best respiratory protection for your workplace. There are three types of respiratory protection available.

|

Negative Pressure RespiratorsNegative pressure face masks rely on the wearer to draw air through the filters using their own breath. Available in disposable half face mask for single-use or reusable half or full-face mask respirators. |

|

Positive Pressure RespiratorsThese respirators utilise a battery-operated unit that propels air through the filters. Available in reusable half or full-face respirators. |

|

Air-Supplied RespiratorsThese respirators supply clean air as opposed to filtering the air in the atmosphere. Full-face masks are used with air supplied respirators. |

All respirators should be fit tested to ensure they are protecting against harmful particles entering the wearer's lungs.

Disposable Negative Pressure Respirators

Disposable respirators are single-use face masks that protect against dust, mists and fumes, depending on their ratings. There are a variety of shapes and features available for disposable respirators. Disposable respirators can offer P1 or P2 protection against particles.

Disposable respirators are single use only. Your respirator should be changed when breathing through the mask becomes uncomfortable or difficult or the respirator is soiled, moist or damaged in any way.

|

Pre-Formed or Flat FoldFlat fold masks come ‘flat-packed’ and need to be expanded before wear. They generally have a better fit as they are flexible and can mold to an individual’s face shape. Pre-formed are packaged ready to wear. Browse the Pre-Formed or Flat Fold respirators here |

|

Valved or Un-ValvedActivated carbon filters assist with removing nuisance odours and offer protection from low levels of specific gases and vapors. |

|

Carbon LayeredActivated carbon filters assist with removing nuisance odours and offer protection from low levels of specific gases and vapors. |

Can You Reuse Disposable Respirators?

You should not reuse disposable respirators as they are designed for single use. Used respirators can also contain contaminants from what they have filtered during their last use. Always dispose of your respirator if it is damp or damaged in any way.

How to Fit a Disposable Respirator Correctly

Donning and doffing respirator masks may seem simple but if masks do not fit correctly, harmful particles may enter the lungs. A mask is fit correctly when there is a complete seal around the mouth and nose, so no unfiltered air can make its way in.

Make sure you are clean-shaven when wearing a respirator, even stubble can affect the seal of the respirator. Always follow the manufacturers instructions for fitting respirators as models may differ.

Check your respirators fit by covering the mask with your hands, then inhale. If you have a good fit the mask will draw in and you won’t feel any leaks around the seal of the mask.

Masks should be fit tested to ensure optimal protection is achieved.

|

Step 1.Hold the mask in hand with the nose piece up. Allow headbands to hang freely. |

Step 2. Position the mask under |

Step 3. Pull the headband over the head. If the respirator has two straps position one at the bottom of the head, the other near the crown. If available, adjust tension straps to achieve a close fit. |

Step 4.Check fit and press |

Get your respirator mask fit tested to ensure you are protected against harmful particles.

Reusable Negative Pressure Respirator Types

Reusable respirators come in both half-face and full-face varieties, both of which offer protection from various particulates, gases and vapors.

Reusable respirators can offer P1, P2 or P3 (full-face respirators only) protection against particles. Some filters also offer protection against vapors and gasses. Reusable respirators are often sold without filters, filters need to be connected to the respirator to protect wearers against particles, vapors or gasses.

|

Half Face RespiratorsHalf face masks provide a seal which fits over the nose and under the chin. Combined with appropriate filters, a half face mask will provide protection against particulates, gases and vapors.

|

|

Full Face RespiratorsA full face mask covers the eyes and face which provides protection against irritating vapors, mists, and splashed chemicals. Full face masks provide a better seal and therefore, protection compared to half face masks. Converting from a half face mask to a full face mask with a P3 particulate filter provides 50 times more protection.

|

How to Tell the Level of Protection a Respirator Filter Provides

When selecting respiratory protection products it is important to choose a respirator that will provide the appropriate level of protection for its intended environment.

Once you have completed an assessment of the specific risks in your working environment, understanding protection classifications will help you select the correct product to keep the user safe during exposure to harmful contaminants.

Australian Particulate Respirator and Filter Standards

Particulate filter face masks are divided into three classes under the AS/NZS 1716, respiratory protective devices, standard for use in Australia and New Zealand.

P1 Respirators & FiltersLow-efficiency filter for protection against mechanically generated particles, for example, silica or |

P2 Respirators & FiltersMedium-efficiency filter for use against mechanically and thermally generated particles. Protects against submicron thermally generated particles, for example, metal fumes, fertiliser and bush fire smoke, as well as bacteria and virus particles like those generated by COVID-19 and |

P3 Respirators & FiltersHigh-efficiency filters are used for protection against highly toxic or highly irritant mechanically or thermally generated particles, for example, insecticides, radionuclides and beryllium. Particle filters can only receive a P3 classification when worn with a full face piece. |

|

Vapor & Gas Filters

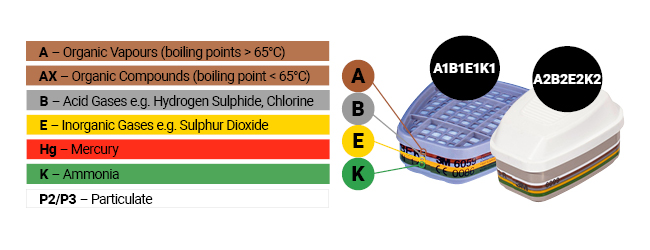

These filters are designed to protect against specific vapors and gases using absorbent material to filter the vapor or gas molecules. They are marked according to the vapors and/or gases they protect against, usually more than one, and are classed by absorbency.

- 1 – Low to medium absorption

- 2 – Medium absorption

- 3 – High absorption

Higher absorbency indicates a higher level of protection against harmful gas or vapor molecules. There are a number of markings on vapor and gas filters that indicate the specified protection, as shown in the table. Filters will be labelled with the specific protection and the level of that protection, as shown in the graphic. E.g. K1 suggests a low to medium level of protection against ammonia. The filter shown protects against organic vapors (boiling points >65°C), Acid Gases, Sulphur Dioxide and Ammonia, all at Class 1 absorbency.

Combination filters are also available, which are designed to protect against particles, vapors and gases. Combination filters will also be marked to indicate the specific vapor/gas they protect against.

How Often Should Respirator Filters be Changed?

During use particles will build up in the filter, slowly allowing less air to pass through. This is known as breathing resistance. Filters should be changed when breathing resistance makes it too uncomfortable or laborious to breathe properly.

The exact time to change your respirator is a personal choice, dependent on how sensitive you are to breathing resistance but your filter should also be changed if it becomes damaged in any way.

What is the Difference Between P2, N95 and KN95 Disposable Respirators?

Disposable respirators are required to meet different standards around the world. Each standard has different requirements that the product must pass before being able to claim compliance. ATOM Safety has prepared a handy document to compare standards in Australia/New Zealand, the United States and China to what Australians refer to as P2 respirators.

Positive Pressure Respirators

Positive pressure respirators provide a supply of clean air, as opposed to filtering the air in the atmosphere.

|

PAPR (Powered Air Purifying Respirator)

Benefits of PAPR Respirators

Ease of Wear

Air Circulation

High APF (Assigned Protection Factors)

Position of the Filter

When to Wear PAPR Respirators

-

What your potential hazards are

-

If respiratory protection is required

-

If so, what level of respiratory (protection factor) is required